What is the Function of a Matching Layer in Ultrasound?

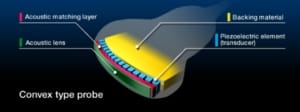

Matching layer--a term most of us have heard but likely have not seen and/or fully understand why a probe needs them. Essentially, the job of a matching layer is to help transfer the ultrasound energy from the elements to the medium (flesh). The matching layer(s) are located between the elements and the lens. They are made of materials that are conducive to achieving better energy transfer, such as epoxy, polyurethane, polystyrene, etc. All probes have at least one of these layers but many have 2 or 3.

The following quote is from a GE patent in regards to matching probe layers:

“Ultrasound probes typically are made up of the transducer piezoelectric ceramic elements sandwiched between the backing or damping layer and a set of matching layers. The backing layers prevent the backward emitted sound waves to echo and ring back into the transducer for detection. The matching layer or layers provide the required acoustic impedance gradient for the acoustic energy from the transducer to smoothly penetrate the body tissue and for the reflected acoustic waves (the returning echo) to smoothly return to the transducer for detection. Without the matching layers, the large impedance difference between the acoustic source (about 33 Mrayls) and the target (about 1.5 Mrayls) would result in loss of transmission and receipt of acoustic energy of up to 90 percent at the interface between the source and the target. Typically, the matching layers are designed to have specific impedance values (e.g., about 15 and 3 Mrayls) and are attached to the transducer.

The stepwise reduction of the impedance at the interfaces minimizes the loss in the transmission and receipt of the returning acoustic signals. A matching layer structure with a gradient of impedance across its thickness from That of the transducer elements (about 33 Mrayls) to that of the body tissue (about 1.5 Mrayls) is the ideal structure for zero loss of signal in the absence of any attenuation of the signal by the matching layer itself. Such a layer would also enhance the fractional bandwidth from a typical 70 percent to 90 percent or more. Such a wider bandwidth allows the transducer to be used selectively in the burst excitation mode at more than one frequency with the accompanying freedom to choose a higher resolution of the image details or longer penetration of the beam energy.

The optimal thickness for each of the matching layers is one-fourth of the wavelength of the central operating frequency of the transducer elements. Thus, the manufacture of the matching layers can be a challenge because of such a small desired thickness. Matching layers thicker than one-quarter wavelength may be used, but they increase the attenuation of the ultrasound intensity with the attendant reduced performance.”

Transducer technologies from Mindray

ComboWave Transducers:

As opposed to traditional transducers, ComboWave transducers are designed with a new type of composite piezoelectric material in order to reduce acoustic impedance on the acoustic matching layer and optimize the acoustic spectrum. Coupled with Mindray's 3T technology, ComboWave linear transducers provides the user with enhanced image resolution and uniformity in areas like the breast, thyroid, and vascular.

Single crystal transducers with 3T technology:

Mindray's 3T technology (Triple-matching layers, Total-cut design, Thermal control), is equipped on new single crystal convex, phased array, and volume transducers to provide the user a wider bandwidth, better penetration, and higher resolution for optimum scanning on applications such as ABD, cardio, and, OB/GYN.

Transducer technologies from Philips

PureWave:

Philips PureWave technology was developed to increase bandwidth and frequency coverage, thus increasing the users resolution and penetration. PureWave utilizes the transducer matching layer and its piezo crystals to significantly improve electromechanical coupling and strain levels.

Transducer technologies from GE

XDClear:

GE XDClear produces a more efficient and pure sound wave by utilizing technologies like single piezoelectric crystal (PMN-PT and PZN-PT) that increases bandwidth, Acoustic Amplifiers to extend bandwidth and sensitivity, and is engineered with piezoelectric material to reduce heat and increases sensitivity and penetration on a wide range of patients.

So how does this apply to our world?

If there is damage to a matching layer we’ll often see weak and dead elements on first call reports resulting in dropout or shadows in the image and airscan. Additionally, with the advent of probe repair, it is quite possible that a matching layer has been completely removed during the relens process! The results would be overall low sensitivity on the first call report and poor axial resolution.